Depending on the different needs of people, MGF carries a wide assortment of home storage solutions.

Our cabinets have been optimized to maximize storage space. We offer multiple models with different divisions and partitions,

mirror cabinets, and storage platforms that can meet multiple customer needs.

The modern mirror cabinet design

integrates powered operated

equipment, intelligent lighting, and

sound system into the design of the

storage function.

Environmental pollution is typically caused by

the reaction of copper sulfate iron powder

with silver. The mirror cabinets produced by

MGF all use environmentally copper-free

mirrors. Because they don’t use copper, they

do not oxidize easily nor produce copper rust,

effectively overcoming the traditional plating

challenges during the production process.

The end result is a higher service life of the

product.

Through various forms of intelligent sensing solutions, it provides users with a pleasant

and comfortable experience with a warm and inviting atmosphere at night.

The light will turn on when it senses a

waving of hand, which makes it suitable

for accent lighting.

It lights up when someone is approaching,

allowing the product to actively cater to

people's needs while saving energy.

MGF bathroom furniture is made of rubber wood imported from Southeast Asia, and a variety of selected E0 grade high-quality environmental

protection panels, which are moisture-proof and anti-corrosion, and a rich variety to meet different functional needs.

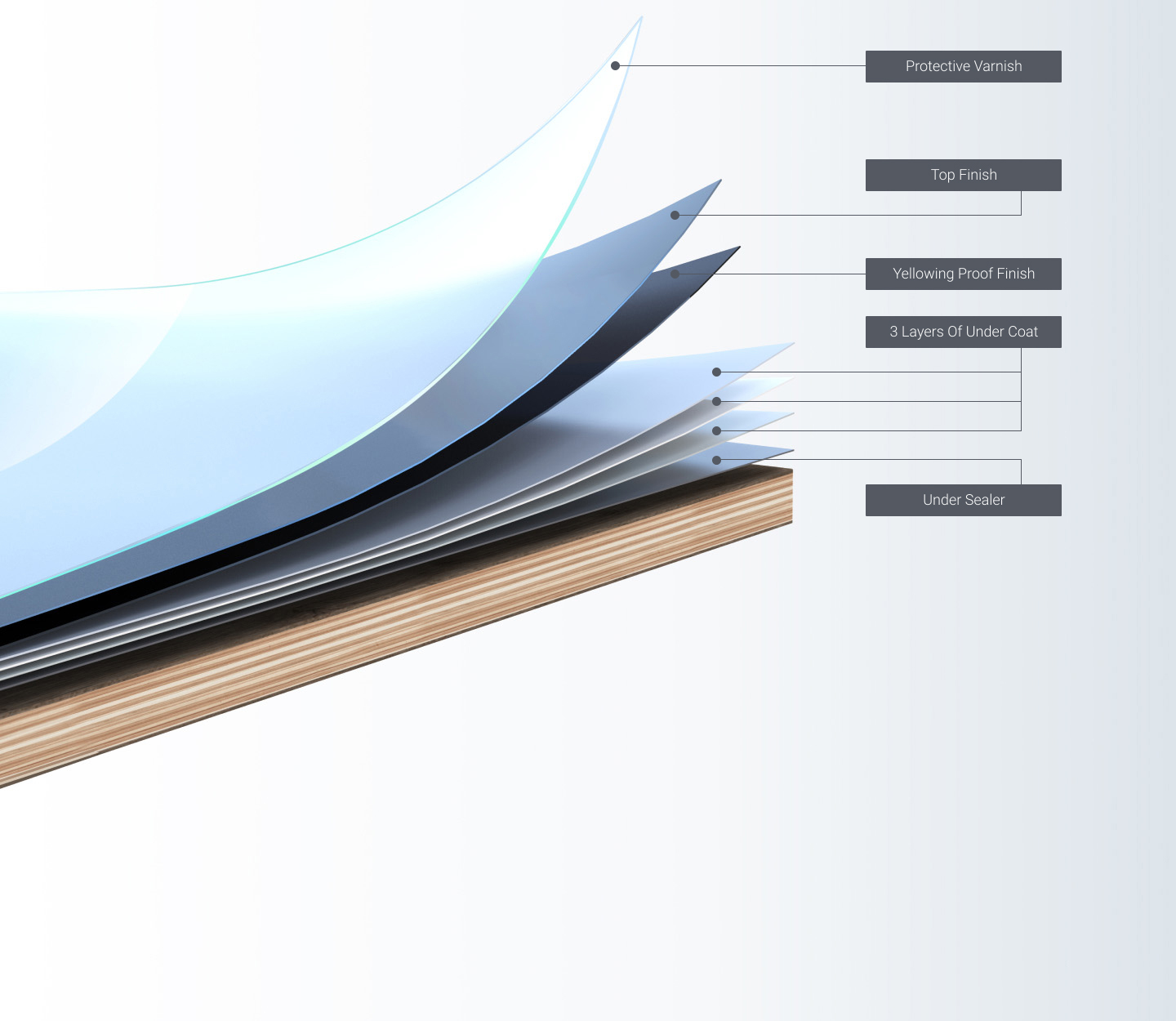

Our products are painted in a process that consist of a four-layer primer, two-layer paint, one layer of wax,

multi-layer waterproof, moisture-proof and deformation-proof protection.

Solid Wood: Mostly used for load-bearing structures such as cabinet legs and panels with carved patterns.

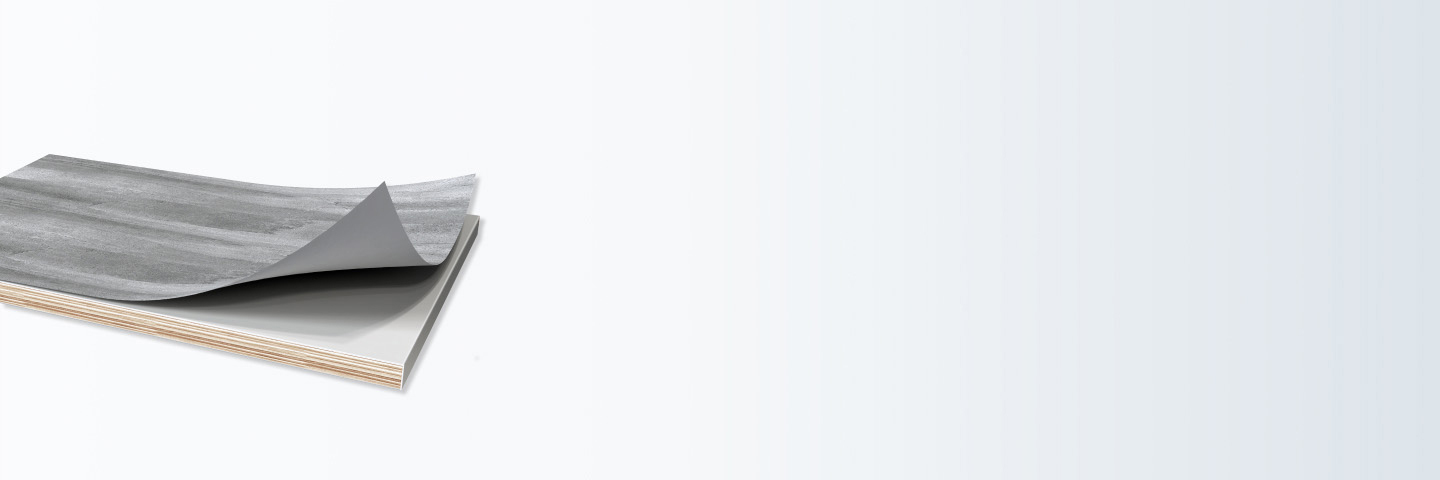

Plywood: good deformation recovery performance in humid environments, mostly used for the base material of paint or paint-free board.

Hdf / Mdf: The board is softer, impact-resistant, high-strength, has a uniform density distribution, and is easy to finish.

Wood Particle Board: The raw material is a natural wood structure, and the expansion rate after being damp is very small, and it will not cause cracking.

Particle Board: Low formaldehyde emission, low environmental impact, light-weight, strong, and durable.

Solid wood veneer can be restored to its

original texture. MGF uses solid wood

veneer technology which enables us to add

large round corners without causing warps.

In addition, the production process uses a

higher standard than the industry average.

MGF uses a melamine veneer that

highly simulates the texture of various

natural or machined materials. At the same

time, it uses round corner bending process

technology, which can effectively prevent

warping regardless of the veneer or edge

trim used.

We use E0 aldehyde paint to ensure

a healthy working environment for

our workforce.